Power Plant Service and Maintenance

Power Plant Maintenance

High-quality maintenance across manufacturers

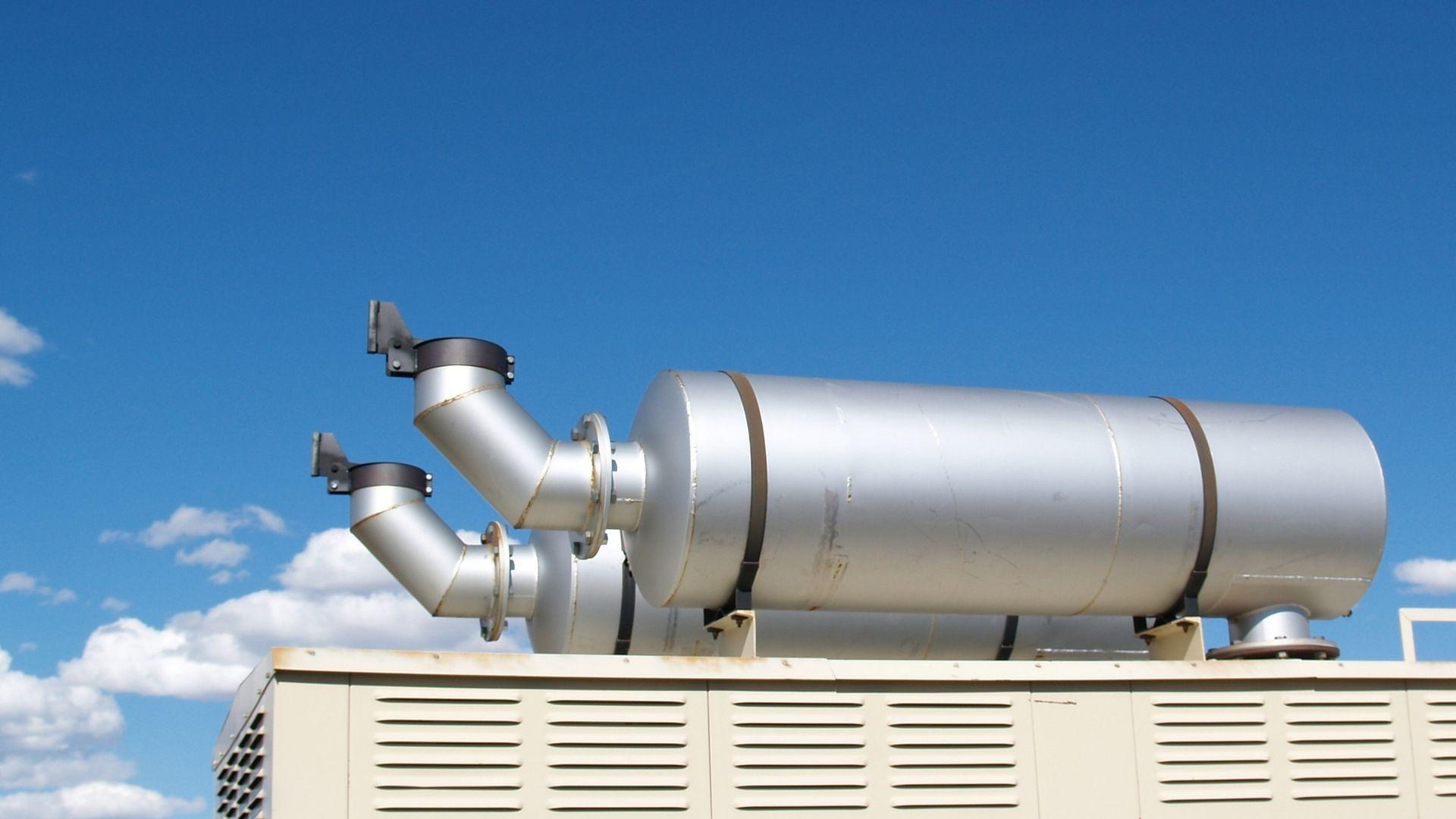

USP&E - Customer Service and Maintenance Agreements (CSMA) Every piece of Caterpillar, Cummins, Rolls Royce and Wartsila equipment we sell at USP&E is designed and built to provide maximum productivity and operating economy throughout its working life.

Increase the life span of your power generation equipment with USP&E Global!

Partnership Approach to Power Plant Operation & Maintenance

A CSMA is a partnership between you and USP&E that will help you succeed by leveraging our equipment management expertise. CSMA`s are an excellent tool for maximizing the asset life of your power generation equipment. A CSMA can reduce these and other costs by placing a variety of service duties into the expert hands of your USP&E technicians . From operator to equipment manager and service technician. A CSMA can cover any or all of your equipment management needs, maximizing the value of your power generation assets.

What can you expect?

We specialize in Power Generation, all our efforts are focused to ensure maximum asset life while minimizing asset expenses and wear.

USP&E's O&M Capabilities

Services

We provide consistent products, services and support wherever your facilities are located. When it comes to customer satisfaction, our 100% commitment to honesty, integrity and excellence is what drives customers back to us again and again. USP&E is dedicated to growing our operations by positive word-of-mouth. The bottom line is that, no matter the hour, no matter the deadline, we always put our client's needs ahead of our own.

Capacity

We have state-of-the-art paved and enclosed warehousing, complete with docks, cranes, forklifts, and extensive inventory. Our professional staff is trained in customer service protocol geared toward both domestic and international clients. USP&E is designed and managed to exceed your expectations when it comes to repairs, maintenance, used generator inventory, expedited parts shipping, refueling and full turnkey installations. We offer same-day order processing from small parts to large equipment.

Expertise

Let our expertise save you as much as 20% per year in fuel oil, spare parts costs and asset life efficiencies. We KNOW the equipment we sell. Our Onsite Diesel Service and Maintenance Teams provide operational precision and detailed reporting. With many years in the field, our teams of professionally trained prime power service technicians have the experience, dedication and management skills required to maximize fuel efficiencies and asset life, while minimizing equipment failures. Whether working in South America or North West Africa, USP&E has the capability and resources to handle all your power plant maintenance and service needs so that you can focus on running your business.

Clients Around the Globe

USP&E has successfully completed turnkey installation, start up, maintenance and emergency repair projects in North America, Africa and around the World. Our Clients Include:

A Partnership That Gets More Done.

In the end, a CSMA is a partnership between you and USP&E that will help you succeed by leveraging our equipment management expertise. With a CSMA, you get more than just a piece of our Power Generation Equipment, you get the support of our entire company.

CSMA's are an excellent tool for maximizing the asset life of your power generation equipment. Agreements can also be written after the sale to help you control costs and improve availability. You get access to trained experts who know more about your Caterpillar, Cummins, Rolls Royce and Wartsila equipment than anyone else. USP&E can provide service in a more timely, efficient and cost-effective manner than anyone else. You will have direct contact numbers to USP&E technicians whom you have met in person and know by name. Ultimately, you save money, improve availability and have more time to concentrate on other important aspects of your business.

All of these factors impact your bottom line. A CSMA can reduce these and other costs by placing a variety of service duties into the expert hands of your USP&E technicians. It sounds simple, but the fact is, you may wear a number of hats in your business - from operator to equipment manager and service technician. A CSMA can cover any or all of your equipment management needs, maximizing the value of your precious power generation assets.

What to Expect From Your Onsite Power Team

Your technicians at USP&E do not sit in corner offices in the air conditioning while others do all the work. Our diesel technicians and engineers are very proud to roll up their sleeves and lead by example when it comes to absolutely any task, no matter how big or how small. Furthermore, exclusively specializing in Power Generation, all our efforts are focused to ensure maximum asset life while minimizing asset expenses. Our highly competent team of dynamic service managers are also efficient and proactive technicians ranked in the top 5th percentile of their industry. Our teams are professionally educated and formally mentored in the latest generator technologies and state-of-the-art tools. With access to USP&E's world class parts inventory system and a huge supply of spare parts specifically ordered and stocked for your equipment, NO ONE knows or is better prepared, to care for your diesel generators like USP&E. At USP&E, Power is our business.

Ready to have an elite energy team assist you with your project?

O&M Training

This training program is directed towards all of our personnel who are involved in plant maintenance including operators, maintenance technicians, engineers, craftsmen and management. Our Objective is to instruct techniques used in the most modern power plants to measure on an ongoing basis, the rate of deterioration of equipment, analysis and interpretation of such information, and the resultant implementation of predictive maintenance.

Condition Monitoring

- Diesel Power Plant Operation

- Combined Cycle Technologies

- Distribution System Training

- Environmental Protection Control

- Electric Utility Management

- Electrical Relay Test & Maintenance

- Electrical Troubleshooting Skills

- Electrical Fundamentals

- Gas Turbine Power Generation

- Heat Rate Optimization

- Hydro-Electric Power Plant Operations

- Steam Power and Co-Generation

- System Protection Technology

- Power Plant Control Room Operator Training

Power Plant Condition Monitoring

This program is aimed at all personnel who are involved in power plant maintenance including operators, maintenance technicians, craftsmen and management. Our Objective is to present techniques used in modern power plants to measure on an ongoing basis, the rate of deterioration of equipment, analysis and interpretation of such information, and the resultant implementation of predictive maintenance.

Diesel Power Plant Operation

This program is designed to aid in upgrading knowledge and understanding of diesel power generation. It covers the practical aspects of operation and maintenance of installations including local, remote control and monitoring. The program is presented at the technician level.

Distribution System Training

After a brief review of electrical fundamentals, this program moves on to cover various aspects of distribution system technology. Topics include distribution networks and equipment, system protection, control and automation, equipment testing and maintenance, and the distribution system operator's role. It is presented on the technician level and knowledge of basic electrical theory is assumed.

Environmental Protection Control

This program is designed to aid in upgrading knowledge and understanding of environmental concerns as they relate to thermal power generating plants. It covers most of the common equipment and processes in use today to ensure that the power generation plant is in compliance with environmental legislation.

Electrical Troubleshooting Skills

This series of award winning interactive CD ROM training programs are ideal for learning proven troubleshooting techniques and applying them in a very realistic simulated environment.

Electrical Fundamentals

This series will provide you with an overall understanding of Electrical Fundamentals including Ohms Law, AC Circuits, Transformers and Three Phase Systems.

Gas Turbine Power Generation

This program will train personnel on the operation and maintenance of gas turbines and associated equipment including combined cycle operation.

Heat Rate Optimization

This program is designed to aid in upgrading knowledge and understanding of the integrated fossil fuel power plant, and improve the operator's ability to optimize thermal efficiency and equipment reliability, thereby improving the plant's economic performance. This program is available in both Imperial and Metric forms.

System Protection Technology

This program will train personnel on the principles of protection systems, including different schemes used in the protection of: generators, buses, transmission & distribution lines, transformers, motors, etc.

Power Plant Control Room Operator Training

Provides Plant Control Room Operators with the knowledge and skills required to operate a power plant Distributed Control System (DCS) and associated plant systems. Each module in the course describes the plant system, associated system controls and typical procedures used during, startup, normal and shutdown operations.

Paving the way for the energy sector

The USP&E CSMA: Decrease Downtime, Increase Reliability and Help Reduce Unplanned Repair Costs

Unexpected downtime. The two words wreak havoc on the most attentively managed power projects, creating a whirlwind of subsequent problems. Successful businesses take advantage of preventive maintenance (PM) and service programs to not only regulate downtime, but also to enhance reliability while actually decreasing operation and maintenance (O&M) costs.

USP&E Global

Your guide to next level power plant O&M